Screw Cutting with Kinetic Engineering: Precision in CNC Machining

26 June 2024

Achieve unparalleled precision for your threaded components with Kinetic Engineering’s CNC screw cutting services. Learn about the importance, benefits, and applications.

At Kinetic Engineering, we understand the critical role precision plays in any engineered component. When it comes to threaded parts, achieving the perfect fit and function is paramount. That’s where our expertise in CNC screw cutting comes in.

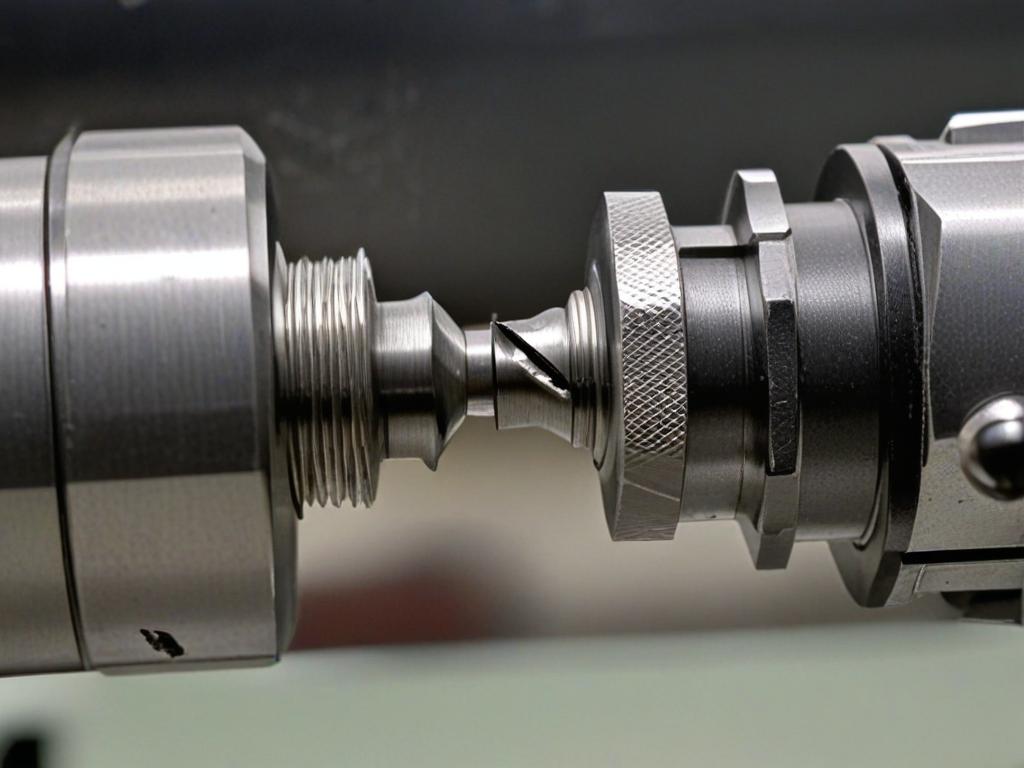

This advanced machining process utilises computer numerical control (CNC) technology to create internal and external threads with unmatched accuracy and repeatability.

The Power of CNC Screw Cutting

Traditional screw cutting lathes rely on a lead screw and change gears to translate rotary motion into a linear movement for thread creation. While effective, this method can be susceptible to inaccuracies due to mechanical wear and backlash.

CNC screw cutting eliminates these limitations. The CNC system precisely controls the cutting tool’s movement based on a pre-programmed digital model. This ensures unmatched accuracy, superior repeatability, reduced lead time and minimised material waste.

The Importance of Screw Cutting

Screw cutting is a crucial process in CNC machining, as it involves creating precise threads on a screw or bolt. The quality of the screw cutting process can significantly impact the overall performance and reliability of the final product.

In CNC machining, screw cutting is used to create threads on screws, bolts, and other fasteners, which are then used in a wide range of applications, including construction, automotive, aerospace, and more.

The Benefits of Precision Screw Cutting

Precision screw cutting offers several benefits, including:

• Improved Performance: Precision screw cutting ensures that the threads are accurately cut, resulting in improved performance and reliability of the final product.

• Increased Efficiency: Precision screw cutting reduces the risk of errors and rework, resulting in increased efficiency and reduced costs.

• Enhanced Safety: Precision screw cutting ensures that the threads are accurately cut, reducing the risk of accidents and injuries.

• Improved Quality: Precision screw cutting ensures that the threads are accurately cut, resulting in improved quality and reduced defects.

How Kinetic Engineering Can Help

At Kinetic Engineering, we have extensive experience in screw cutting and CNC machining. Our team of experts uses state-of-the-art equipment and techniques to ensure precision in screw cutting. We can help you achieve precision in your screw cutting needs by:

• Providing Customized Solutions: We can provide customised solutions to meet your specific screw cutting needs, including precision screw cutting, thread cutting, and more.

• Using State-of-the-Art Equipment: We use state-of-the-art equipment and techniques to ensure precision in screw cutting, including CNC machining centres, lathes, and more.

• Offering Expertise: Our team of experts has extensive experience in screw cutting and CNC machining, ensuring that you receive the highest level of precision and quality.

Partner with Kinetic Engineering for Flawless Screw Cutting Solutions

Precision screw cutting is a critical process in CNC machining, and Kinetic Engineering is committed to providing precision in screw cutting. Whether you need precision screw cutting for a specific application or require customized solutions, we can help you achieve precision in your screw cutting needs.

Optimised by: Netwizard SEO