Modern Techniques in Screw Cutting Services for Complex Designs

24 January 2025

Kinetic Engineering offers advanced screw cutting services in Sydney, using modern techniques for complex designs. Ensure quality with our expert solutions.

At Kinetic Engineering, we specialise in providing high-quality screw cutting services in Sydney. With the latest technologies and expertise, we can handle even the most complex designs with precision, ensuring reliable and efficient results for your projects.

What are Screw Cutting Services?

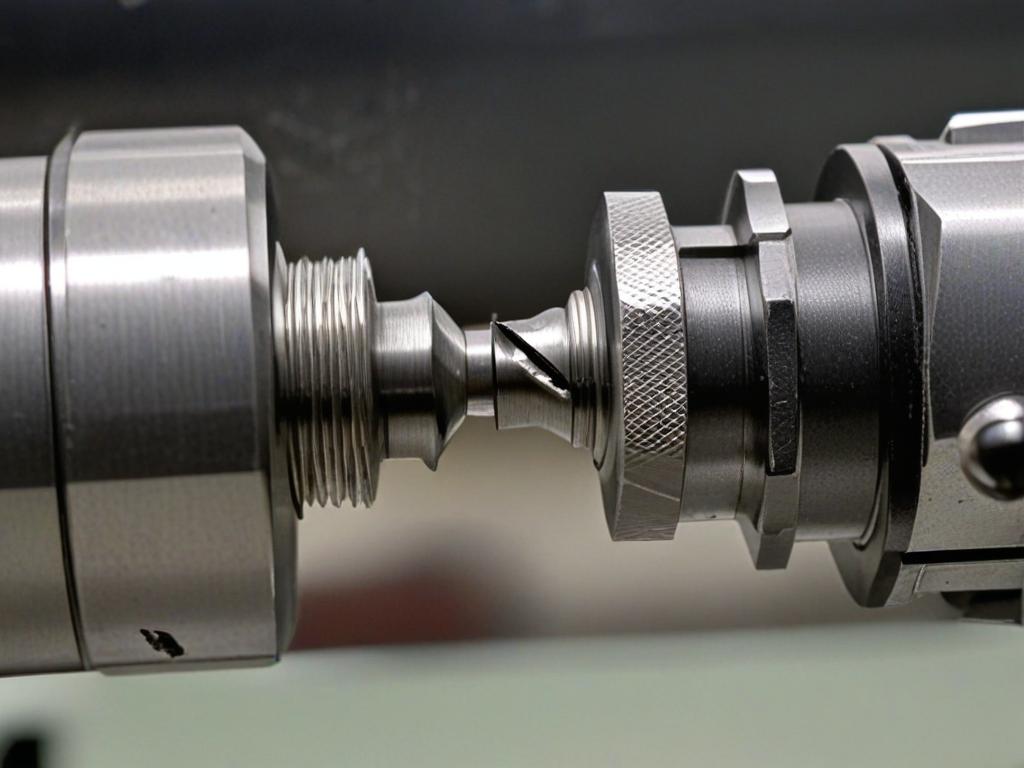

Screw cutting is a machining process used to create threads on a metal or plastic workpiece, forming the helical grooves that allow screws to be inserted into corresponding threaded holes or other screw components. This process is crucial for producing screws, bolts, and other fasteners that are used in a wide range of industries, including construction, automotive, aerospace, and manufacturing.

The threads on a screw are important for providing grip, ensuring that the screw can be securely fastened, and enabling the screw to hold components together. Screw cutting can be done using several methods, depending on the complexity, material, and production volume required.

Modern Techniques for Complex Designs

In today’s manufacturing and engineering industries, the demand for precision and complexity in screw cutting services has reached new heights. As industries evolve and designs become more intricate, manufacturers are continually pushing the boundaries of screw cutting techniques.

Modern technology, coupled with innovative processes, has revolutionised screw cutting, offering enhanced precision, faster turnaround times, and the ability to create complex screw designs that meet specific application requirements.

Some of the cutting-edge techniques used in screw cutting services today are as follows:

• Computer Numerical Control (CNC) Machining: CNC machining has become the backbone of modern screw cutting. This technology utilises computer programs to control the movement of cutting tools, which ensures that screws are produced with unparalleled accuracy. CNC machines allow manufacturers to design and cut screws with extremely tight tolerances, something that is often required for complex and intricate designs. CNC machines are also programmable to create multi-stage processes, which is particularly beneficial when dealing with screws that need to be machined in multiple steps, such as multi-threaded screws or screws with specific head designs.

• Laser Cutting and Laser Engraving: Laser cutting has emerged as a highly effective method for creating complex screw designs, especially when dealing with fine or delicate materials. This technique uses a focused laser beam to cut and engrave metal, allowing for intricate screw head designs, such as those required in the aerospace and medical fields. Laser engraving can also be used for adding identification markings or serial numbers to screws, which is particularly important in industries where traceability and compliance with regulatory standards are critical.

• Thread Rolling: Thread rolling is a modern cold-working process that forms threads on a screw by applying pressure to the workpiece between two rotating dies. This technique results in high-strength threads that are often more durable than those cut by traditional methods. Thread rolling is particularly useful for creating screws that need to withstand high levels of stress and wear, such as in automotive or industrial machinery applications. In addition to strength, thread rolling produces a smooth surface finish, which reduces the risk of friction and wear in threaded components. This makes it a preferred method when cutting screws with complex threads.

For companies looking to produce screws with high precision, strength, and complex geometries, embracing these modern screw cutting methods is essential. Partner with Kinetic Engineering today so we can help push the boundaries of what’s possible in screw cutting and manufacturing.

Optimised by: Netwizard SEO