Meet Tight Tolerances: Turning Services for Exacting Fabrication Needs

07 March 2024

Achieve accuracy and quality in every part with turning services by Kinetic Engineering. Meet tight tolerances with turning for exacting fabrication needs.

When it comes to ensuring the quality and functionality of machined parts and components, industries can turn to turning services. These services can achieve these exacting fabrication requirements by providing the precision and accuracy needed to meet stringent specifications.

The Significance of Tight Tolerances

Tolerances refer to the allowable deviation from a specified dimension or geometric characteristic in a machined part. Tight tolerances mean a narrow range of acceptable variation, which requires precise machining techniques to achieve. Parts with tight tolerances are often found in industries like aerospace, automotive, medical, and electronics as they require precision and reliability.

Now, two things that must be considered to achieve tight tolerances are the materials and tooling. A careful selection of these things can optimise machining performance and dimensional stability. We, at Kinetic Engineering, choose the most suitable materials for the application, considering factors like hardness, thermal conductivity, and machinability. Applications requiring tight tolerances can take advantage of high-performance alloys, advanced ceramics, and engineering plastics.

Major Precision Turning Techniques

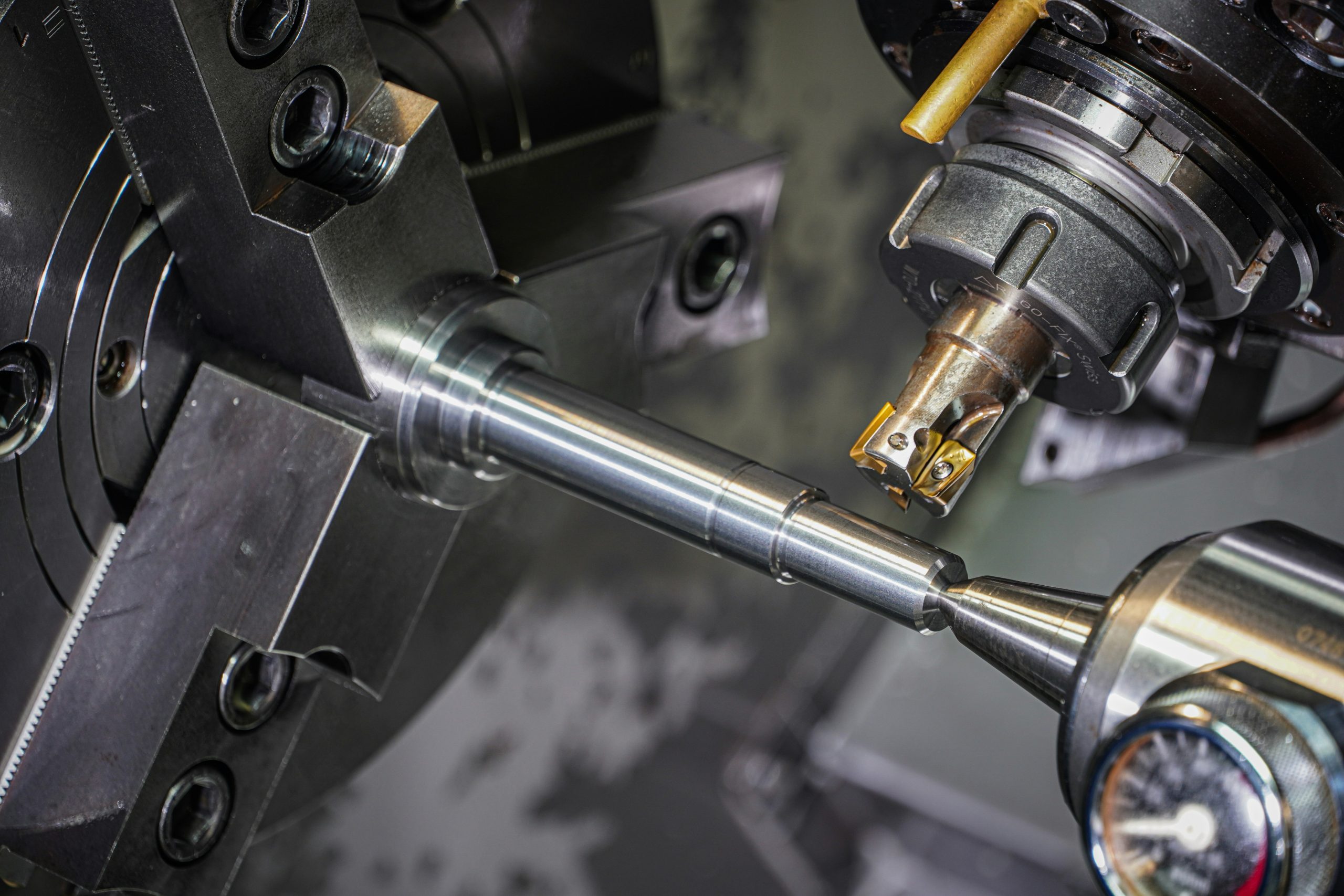

A process that can be used to produce quality parts is turning. It is a machining process that can create cylindrical parts by removing material from a rotating workpiece with a cutting tool. Our team at Kinetic Engineering employ a variety of precision turning techniques to meet tight tolerances. Some of these techniques are as follows.

• High-Speed Machining: We utilise advanced CNC turning equipment capable of high spindle speeds and rapid tool changes to achieve tight tolerances with minimal runout and vibration.

• Micro-Machining: We likewise employ specialised cutting tools and techniques to machine miniature parts and features with micron-level accuracy and surface finish.

• Multi-Axis Machining: We even leverage multi-axis CNC lathes and turning centres to machine complex geometries and contours with precision and repeatability.

Quality and Consistency are Crucial

To monitor part tolerances and ensure adherence to specifications, we carry out frequent dimensional checks and quality inspections during machining. Kinetic Engineering also implements rigorous quality assurance measures to verify part dimensions, surface finish, and geometric accuracy. Advanced metrology equipment pieces can be used to inspect finished parts and ensure compliance with tight tolerance requirements.

All processes covered by our turning services can help achieve the results needed by different industries and sectors. The aerospace industry, for instance, can turn to turning services to produce turbine blades, engine shafts, and landing gear parts. Engines, transmissions, steering systems, and chassis assemblies for the automotive industry can also be produced out of turning services. Even the medical industry can opt for these services to manufacture surgical instruments, implants, and prosthetic devices with precise dimensions and biocompatible materials.

Turning services by Kinetic Engineering are guaranteed to meet tight tolerances and exacting fabrication needs across various industries. We maximise precision turning techniques, advanced equipment, and quality assurance measures to achieve the required dimensional accuracy and surface finish in machined parts. Whether in aerospace, automotive, or medical applications, our turning services provide the precision and reliability needed to produce high-quality components that meet the most demanding specifications.

Optimised by: Netwizard SEO