CNC Machining: Shape the Future of Manufacturing with Machining Centres

10 January 2024

Revolutionise manufacturing in Sydney with CNC machining centres. Utilised by Kinetic Engineering, ensure precision in modern production. Call (02) 9153 9911.

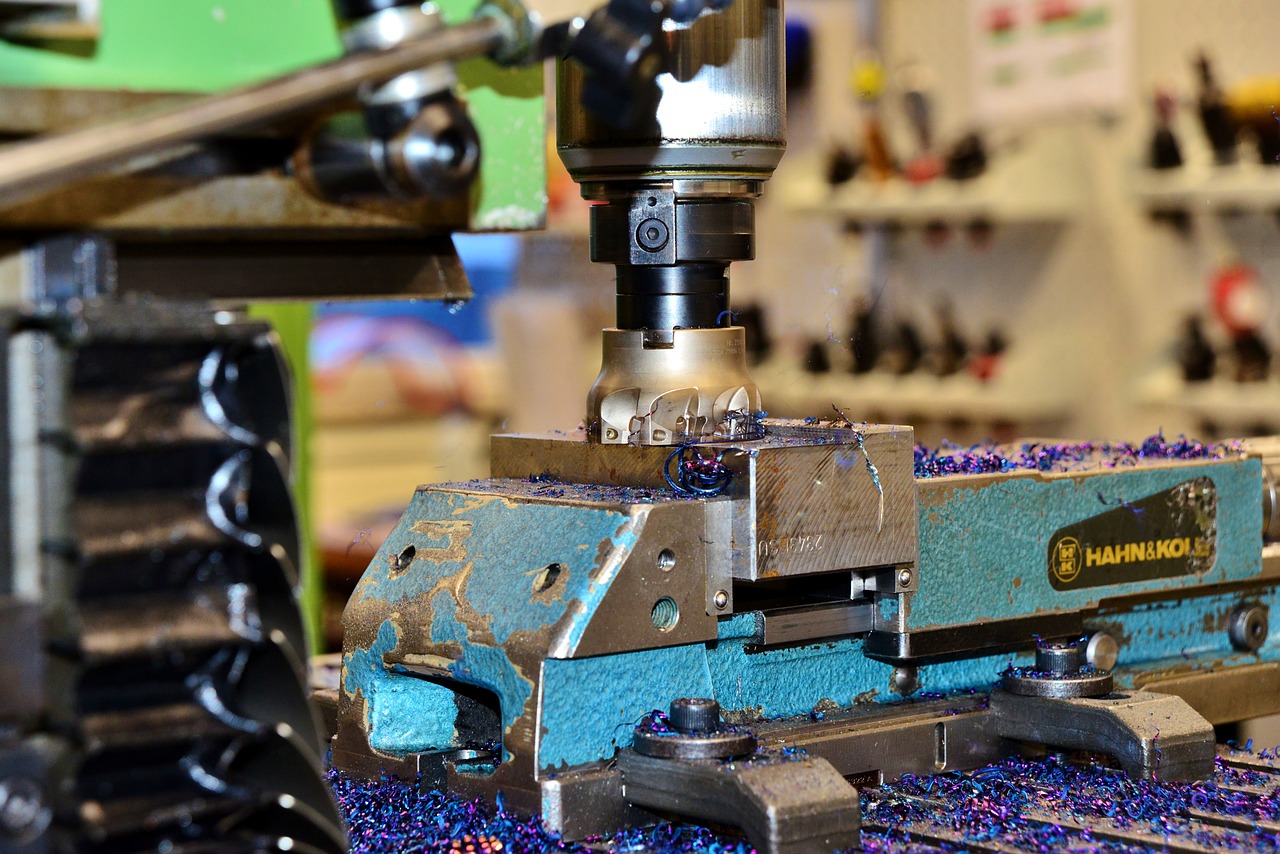

Modern manufacturing has been evolving rapidly due to the advancements integrated into a variety of machining tools and processes. One of these processes is computer numerical control (CNC) machining. Central to this process are machining centres, which are powerful hubs that can bring together innovation and precision.

The Gradual Rise of CNC Machining

CNC machining has evolved from traditional manual methods to computer-controlled precision. What sets it apart is its ability to automate and control tool movements with unparalleled accuracy, enabling the production of intricate and complex parts. The introduction of machining centres takes this precision to the next level by consolidating machining operations into a single, integrated system.

Maximising CNC Machining Centres

CNC machining centres are tools often utilised for CNC machining. At Kinetic Engineering, we carry out machining processes through machining centres. Some notable components of CNC machining centres include the following.

• Multi-Axis Capabilities: One of the notable features of machining centres is their multi-axis capabilities. Traditional machining is limited to three axes (X, Y, and Z), while machining centres can operate in multiple axes simultaneously. Their versatility enables the production of complex geometries and intricate components.

• Programmable Workholding: Machining centres feature programmable workholding devices. They can be customised to secure different types of workpieces, providing flexibility and adaptability in manufacturing various components without needing manual adjustments.

• Automated Tool Changers: Machining centres are equipped with automated tool changers, allowing for seamless transitions between different tools during machining. This automation eliminates the need for manual tool changes, reducing downtime and enhancing overall efficiency.

• High-Speed Machining: Modern machining centres are designed for high-speed machining, allowing for faster cutting and machining operations without sacrificing precision. This capability significantly reduces production times and enhances overall productivity.

CNC Machining Centres: Capabilities

At Kinetic Engineering, we use machining centres to carry out a variety of processes.

For one, we can process a wide range of materials to generate products. The precision and versatility of CNC machining centres make them well-suited for the intricacies of working with cutting-edge materials, contributing to advancements in automotive, aerospace, and many more industries. We can then integrate machining centres into the processes carried out in Industry 4.0. We can install them alongside networked systems, allowing for real-time monitoring, data analysis, and remote control.

Machining centres can even be utilised for additive and subtractive manufacturing integration. We use machining centres to conduct additive and subtractive methods, allowing for the precision machining of additively manufactured components. This capability opens new possibilities for design complexity and material combinations. Ultimately, we utilise machining centres for prototyping and rapid production runs as they can process materials quickly and accurately.

CNC machining centres shape the future of how Kinetic Engineering produce intricate and precise components. As industries continue to push the boundaries of design complexity and material innovation, machining centres will play a pivotal role in realising the vision of efficient, sustainable, and technologically advanced manufacturing processes.

Optimised by: Netwizard SEO