CNC Machining Services in Sydney for Electronics: High-Accuracy Components

06 June 2025

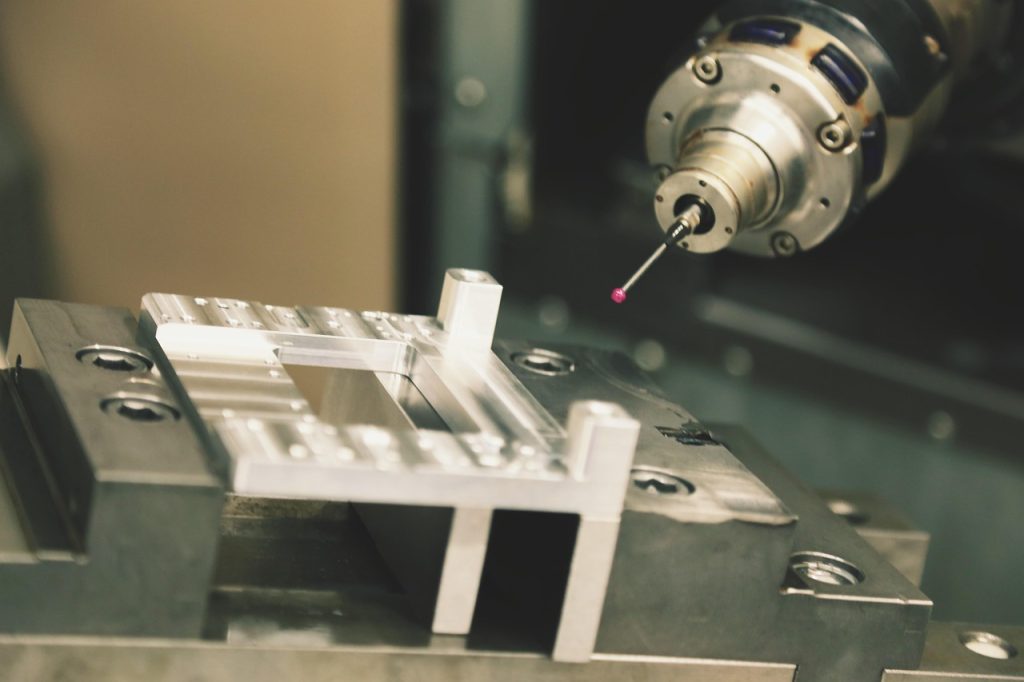

Optimise your electronics with CNC machining services in Sydney, backed by Kinetic Engineering’s precision-focused Australian manufacturing approach.

CNC Machining Services for Compact and Miniaturised Electronics

The progressive miniaturisation of electronic devices has increased demand for precise and dimensionally stable components. CNC machining addresses these needs by achieving repeatable output across numerous production runs, regardless of scale.

Machined parts such as enclosures, connectors, and mounts require accuracy that tolerates no deviation. CNC processes allow adjustments down to micron levels, enabling seamless integration into circuit layouts or assembled systems without interfering with performance or housing constraints.

Material Selection in CNC Machining Services for Electronics

Aluminium is frequently selected for its lightweight profile and superior heat dissipation qualities. CNC machines can mill aluminium into reliable electronic housings that resist corrosion and ensure thermal efficiency across operational cycles.

Copper, favoured for its excellent conductivity, supports contacts and power distribution components. Meanwhile, engineering plastics like PEEK and PTFE are preferred for insulation and structural parts, with CNC machining ensuring dimensional conformity and performance reliability in both prototyping and production stages.

Custom CNC Machining Services for High-Precision Electronic Applications

Highly detailed electronic systems demand machining solutions that adapt to the dimensional and performance requirements of each component. CNC technology allows precision-driven production that addresses complex part specifications across various sectors.

• Precision Fit for Telecom Assemblies: Geometries are executed with absolute dimensional integrity to eliminate signal disruption and support dense hardware configurations.

• Tolerance Assurance for Medical-Grade Electronics: Machined components are manufactured within strict micron-level tolerances to meet functional reliability in diagnostic and wearable devices.

• Repeatability for Consumer Electronics: Batch consistency is achieved through controlled toolpaths that reproduce identical units for high-volume consumer product assemblies.

• Surface Finish Optimisation: Surface qualities are refined during machining to minimise friction, prevent wear, and support long-term electrical or structural performance.

• Material-Specific Adaptations: Cutting speeds, tooling angles, and feed rates are precisely aligned with material properties to maintain integrity and shape accuracy.

• Complex Feature Integration: Intricate part characteristics such as undercuts, fine threads, and tapered holes are implemented without compromising strength or function.

• Volume Flexibility: Processes scale from single-run prototypes to high-volume production without deviating from dimensional targets or delivery schedules.

High-Performance Results from CNC Experts in Sydney

Through continuous adaptation and innovation, Kinetic Engineering aligns its capabilities with the demanding tolerances and complexities required by today’s electronics sector. Our CNC machining support not only serves the precision standards of modern assemblies but also reflects our commitment to quality and client-driven manufacturing processes.

Secure precision in your electronic assemblies through tailored machining solutions from Kinetic Engineering.

View our CNC machining solutions engineered for high-accuracy electronic fabrication.

Learn how to select the right CNC machining solutions for your needs with this guide: Choosing a CNC Machining Service – 22 Key Factors to Consider

Optimised by: Netwizard SEO