CNC Lathe Machining by Kinetic Engineering and How It Creates Complex Parts

01 December 2023

Create high-quality complex parts with CNC lathe machining by Kinetic Engineering. Craft intricate components for various industries today. Call 02 9153 9911.

Modern manufacturing has benefitted from a range of machining processes to effectively produce different parts and components. Computer numerical control (CNC) lathe machining is one of those processes that can help create intricate and complex products for various industries. From aerospace components to medical devices and automotive parts, CNC lathes have become indispensable in delivering efficiency and precision.

A Quick Background of CNC Lathe Machining

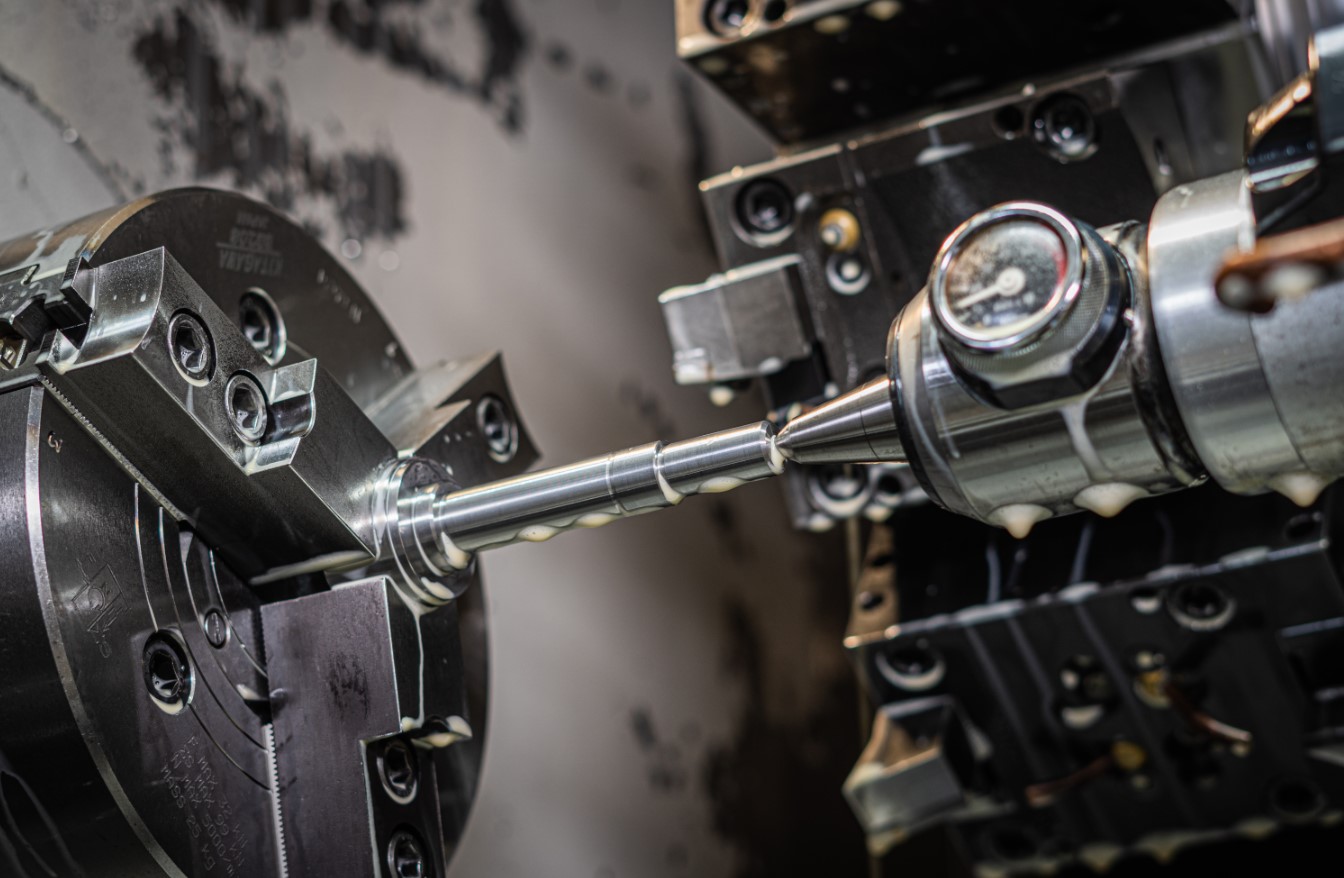

CNC lathe machining is a subtractive manufacturing process where automated computer programs control the movement of a cutting tool. This tool removes material from a workpiece, which is often made of metal, plastic, or other materials, to create the desired shape, size, and finish. CNC lathes are highly versatile machines that can produce an array of components with tight tolerances and intricate geometries, as long as they are programmed and set up appropriately.

The process of CNC lathe machining begins with the design of a 3D CAD or Computer-Aided Design model of the part to be manufactured. Skilled engineers and machinists program the CNC lathe with the precise toolpaths and instructions needed to produce the component. Once set up, the lathe’s computer controls every aspect of the machining process, including the rotation and movement of the workpiece and the cutting tool.

We, at Kinetic Engineering, can produce a variety of complex parts out of different materials thanks to our team’s knowledge and expertise in CNC lathe machining. Partnering with us can help businesses like yours to take advantage of complex parts and components.

CNC Lathe Machining: Advantages and Uses

A wide range of advantages can be obtained when maximising CNC lathe machining. Some of these advantages are as follows.

• Unparalleled Precision: CNC lathe machining offers unparalleled precision. It can repeatedly produce components with tight tolerances, ensuring each part meets exact specifications.

• Complex Geometry: This process excels at creating parts with intricate shapes, contours, and details that would be challenging to achieve manually.

• Highly Efficient: CNC lathe machining is also highly efficient, reducing production time and material waste. Automated processes minimise human error and increase output.

• Cost-Effective: While the initial setup of CNC lathe machining may require investment, it leads to cost savings in the long run due to reduced labour costs and enhanced productivity.

• Ensured Versatility: CNC lathes can work with a wide range of materials, from metals and plastics to composites and exotic alloys, making them suitable for diverse industries.

All the advantages of CNC lathe machining make it useful in many applications. The aerospace industry, for instance, takes advantage of this process to create precision components for aircraft and spacecraft. The medical industry also uses this process to produce surgical instruments, implants, and medical devices. Engine components, transmission parts, and more can likewise be produced by CNC lathe machining for the automotive industry. Even connectors, pins, and other small, intricate parts for electronics can be generated by the CNC lathe machining.

CNC lathe machining by Kinetic Engineering is a cornerstone of modern manufacturing, enabling the production of precise and complex components across diverse industries. We harness the power of CNC technology to craft parts that meet strict quality standards and drive innovation in various sectors.

Optimised by: Netwizard SEO