Manual Machining by Kinetic Engineering Advantages for Small Production Runs

17 November 2023

Attain the benefits of manual machining by Kinetic Engineering for small production runs in Australia. Ensure precision and cost-savings. Call (02) 9153 9911.

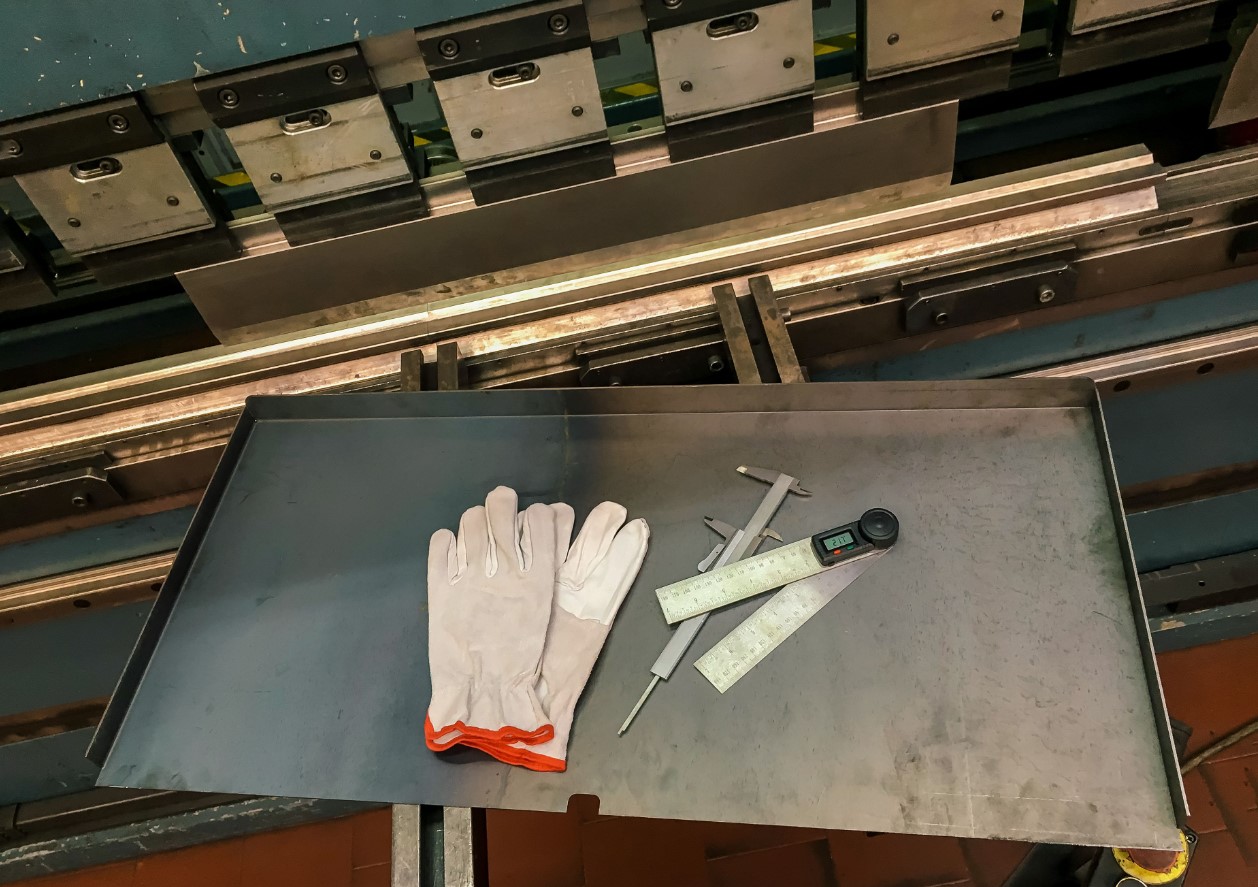

The process of manual machining may seem like a relic of the past, especially with the increasing use of CNC machines and automated manufacturing techniques. However, for small production runs and specialised projects, manual machining remains a valuable and versatile option. We, at Kinetic Engineering, know how valuable this process is, ensuring it can still be maximised when carrying out small production runs and other similar projects.

When you opt for our manual machining service, you can attain the following perks for your small production runs.

Attention to Detail

Manual machining involves the skilful use of hand-operated tools and equipment, which allows our machinists to exercise a high degree of precision and control. Every cut, turn, and adjustment is made with meticulous attention to detail. This level of precision is highly valuable when producing small batches of parts or components without compromising accuracy.

Versatile

Another standout advantage of manual machining is its versatility. Kinetic Engineering can quickly switch between various tools and techniques to accommodate different materials, designs, and specifications. The flexibility of manual machining is invaluable for small production runs that often involve diverse requirements and specifications.

Cost-Effective

While automated CNC machines excel in mass production, they may not be cost-effective for smaller quantities. Manual machining eliminates the need for complex programming and setup, which makes it a cost-efficient choice for small-scale projects. The cost-efficiency of manual machining can translate to savings for businesses that want to produce limited quantities of parts or prototypes.

Superior Quality

Manual machinists are skilled and experienced craftsmen who have honed their expertise through years of training and practice. Their knowledge of materials, tool selection, and machining techniques ensures that each piece is crafted with the utmost care and skill. Our craftsmanship at Kinetic Engineering can result in superior quality products, even in small batches.

Rapid Prototyping

Manual machining is ideal for rapid prototyping, allowing us to create physical models and test designs without the time and expense of setting up automated machinery. This agility is crucial when refining product concepts and bringing innovations to life. It also grants you the opportunity to review and test your intended product specifications before the final production.

Quick Turnaround

Manual machining often offers faster turnaround times for small production runs. Without the complexities of computer programming and setup, our experienced machinists can begin work promptly, meeting your tight deadlines and urgent requirements.

Easy Upkeep

In many cases, manual machining is the preferred choice for maintenance and repair work. When specific components need replacement or refurbishment, we can replicate or modify parts swiftly, which then helps you minimise downtime.

Strong Personalisation

For businesses with unique or specialised needs, our manual machining service provides the opportunity for personalised solutions. We can work closely with clients like you to understand their requirements and create custom components tailored to their exact, needed specifications.

Manual machining by Kinetic Engineering offers a range of advantages for small production runs, making it a viable choice for businesses and industries where quality and efficiency are paramount, even in smaller quantities.

Optimised by: Netwizard SEO