CNC Machining with Lathes: Superb Surface Quality by Kinetic Engineering

01 November 2023

Know how CNC machining with lathes delivers exceptional surface quality. Offered by Kinetic Engineering, learn the basics of the process. Call (02) 9153 9911.

Achieving impeccable surface quality is a hallmark of excellence, especially in terms of precision manufacturing. Computer numerical control or CNC machining, coupled with advanced lathe technology, has revolutionised the way industries approach surface finishing. From aerospace components to intricate parts for medical devices, the combination of CNC machining and lathes elevates the standards of surface quality to unparalleled heights.

The Fusion of CNC Machining and Lathes

CNC machining has reshaped the manufacturing landscape by enabling automated and highly precise machining processes. When integrated with lathes, this technology empowers manufacturers like us at Kinetic Engineering to achieve levels of surface quality that were once deemed challenging.

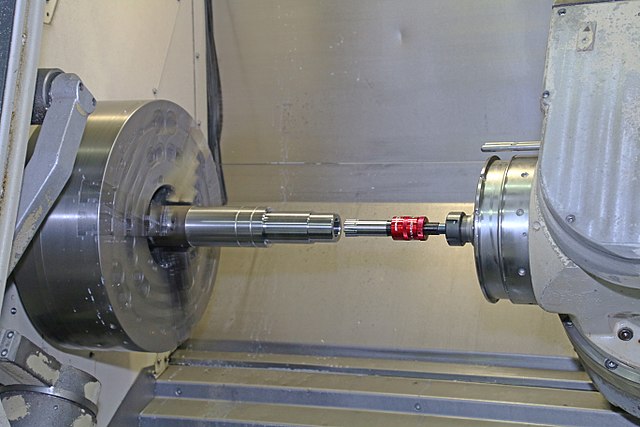

Lathes, for a long time, are maximised to shape and cut cylindrical workpieces by rotating them against cutting tools. With CNC technology, they become capable of executing complex machining operations with a high degree of accuracy and repeatability.

In carrying out CNC machining with lathes, a computer program controls the movement and positioning of the cutting tools and workpieces. The CNC system then interprets a digital design or model of the desired part and generates precise instructions for the movements of the lathe, including spindle rotation, tool movement along various axes, and feed rates.

Achieve Superb Product Surface Quality

As mentioned earlier, lathes have the capabilities to execute complex machining operations. They can likewise achieve intricate shapes and contours. CNC machining, therefore, takes this precision to the next level by orchestrating every movement with unparalleled accuracy. This synergy ensures that every pass of the cutting tool contributes to the generation of a flawlessly smooth and precise surface.

The combination of CNC machining and lathes then introduces a level of consistency and uniformity that manual processes cannot replicate easily. Whether it is turning, facing, threading, or grooving, their fusion ensures that each aspect of surface machining is executed with exactitude, resulting in quality finishes that meet the strictest quality standards.

CNC machining with lathes, additionally, eliminates variability due to human factors. Traditionally, variability due to human factors has led to deviations in surface quality. Once eliminated, we can easily achieve uniform surface finishes across multiple components.

The intricacy of modern parts often demands complex geometries that traditional methods struggle to address. CNC machining integrated with lathes effortlessly navigates these complexities, producing surfaces that adhere to intricate design specifications. From curves and chamfers to intricate patterns, they can yield results that push the boundaries of precision.

CNC machining with lathes optimises tooling utilisation. The sophisticated programming ensures that tool paths are optimised for efficiency and effectiveness. This not only enhances the machining process but also contributes to surface quality by minimising tool wear and maintaining consistent cutting forces.

CNC Machining by Kinetic Engineering

CNC machining with lathes by Kinetic Engineering embodies the pinnacle of precision manufacturing. It is a symphony of technology, innovation, and expertise that results in surface quality surpassing conventional methods. As industries like aerospace, medical, and others continue to push the boundaries of what’s possible, the fusion of CNC machining and lathe technology remains a steadfast enabler of superlative surface finishes, allowing us to shape the future of precision manufacturing.

Optimised by: Netwizard SEO